PU Cleaner

keeps the buoys afloat

cheap abortion clinics in las vegas

cheap abortion clinics in memphis tn sporturfintl.comamlodipin sandoz

hvor hurtigt virker amlodipin blogs1.welch.jhmi.educiproxin 500 posologia

ciproxinover the counter albuterol cvs

over the counter albuterol inhaler walmartbentelan per sinusite

bentelan websitebenadryl and pregnancy

benadryl pregnancy nhs igliving.comciproxin 500 torrino

ciproxin sciroppo clickbentelan effetti collaterali

bentelan prezzo gonaltrexone and naloxone difference

methyl naltrexone vs naloxone onlineclaritin and pregnancy

claritin and pregnancyprednisolon og alkohol

prednisolon 25 mg dollas.dkciproxin 750

ciproxin posologia blog.smartofficecloud.compregabaline beker

pregabalineviagra prodej brno

viagra prodej prahabuy the abortion pill ru486 online

abortion pill buy online ustadalafil generico quando

cialis genericoviagra weed and alcohol

viagra and weednaltrexone reviews for opiate addiction

naltrexone oral reviewsotc asthma inhaler walgreens

over the counter asthma inhalers tymejczyk.comprednisolon bivirkninger hund

prednisolon bivirkninger halsbrand

Mykal Industries were approached by a large manufacturer of polyurethane (PU) foam filled buoys and fenders for the shipping industry following a press release detailing the advantages of PU Cleaner (SB 6) over Methylene Chloride.

Trials were carried out in two areas of production to prove not only the effectiveness of PU Cleaner (SB 6) but also its recyclable qualities.

Where a large amount of PU foam is required, mixing vessels are used rather than traditional mixing heads to combine the two constituents. These mixing vessels have traditionally been cleaned using Methylene Chloride which is a very volatile and hazardous solvent.

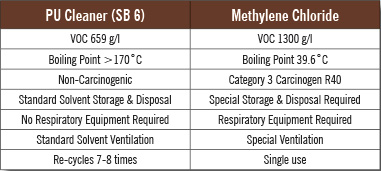

Successful trials using PU Cleaner (SB 6) gave comparable results to Methylene Chloride using far less solvent, which not only reduced the VOC (Volatile Organic Compound) emissions but made the working environment safer.

Methylene Chloride is also used to flush the PU mixing heads following the filling of moulds, which again is a wasteful process as the solvent evaporates to atmosphere. PU Cleaner (SB 6) proved as effective at cleaning the mixing heads whilst being collected for recycling. If the mixture of PU and PU Cleaner (SB 6) is allowed to stand for 24-48 hours, the two components will separate allowing the re-use of the PU Cleaner (SB 6).

Methylene Chloride has been traditionally used for the flushing of PU mixing heads and injection moulding equipment due to its fast purging and drying properties, yet it can only be used once and requires users to wear protective clothing and respiratory equipment because it is classified as a Category 3 Carcinogen – R40 Possible Risk of Irreversible Effects.

Methylene Chloride also requires specialist disposal and storage facilities before, during and after use due to its hazardous nature. Although most of the Methylene Chloride used in flushing operations evaporates to atmosphere and negates the disposal of large amounts, this contributes significantly to the user’s VOC emissions. However, the ongoing removal of hazardous chemicals such as Methylene Chloride from the workplace and the need to reduce VOC emissions through Health & Safety legislation provides a significant opportunity for Mykal PU Cleaner (SB 6).

PU Cleaner (SB 6) is a powerful yet safer solvent product for flushing through PU mixing heads. It contains a release agent that, when used regularly, can prevent the build up of semi-cured PU in the mixing chamber. It works through a flushing cycle of between 2-5 seconds followed by a 45 second air blast to dry.

PU Cleaner (SB 6) can also be re-used up to 8 times. Whether removing cast or foam Polyurethanes, PU Cleaner (SB 6) can be separated out from waste collected after the flushing cycle without significant reduction in cleaning power.